When we started Stickerscape we made the decision that we wanted to manufacture everything ourselves in-house. With the equipment costs involved, this wasn’t a decision we made lightly, but we really wanted to have the control and flexibility that this would give us as a company. If I was putting it kindly, I’d say I’m a real perfectionist (if I was being honest, or if Mike was telling this story, I’d probably be described as being a bit of a control freak!) – but either way having the ability to do things just how you like is a massive plus in our business.

In our quest to get it just right, we’ve tested several hundred combinations of potential media, print settings and production variances. We’ve visited suppliers, imported samples of media from abroad, spent countless days researching online, and Mike has built up quite a profile on certain print forums (worryingly I think he may have quite enjoyed this bit). You can imagine what my house has looked like at various points – we have had test prints everywhere (once I went on holiday and I left Mike my keys – BIG MISTAKE – when I returned there were about 50 test stickers up on the wall right next to our bed!). For months Mike would come over to my house several times a week with the latest batch of test stickers, and we’d spend what seemed like hours with faces pressed up to the walls checking all the current stickers and making notes of what was working best (heaven knows what the neighbours would have thought if they’d seen us).

When we thought about setting up Stickerscape a couple of years ago, and were writing those early to-do lists, we frankly never gave all this any thought. I suppose I just assumed that it would be easy enough to find a media on the market and just use that with some kind of ‘standard’ printer setup. However, it seems it’s not that simple – and whilst we could have taken some shortcuts along the way, that perfectionist thing is hard to shake and we don’t want to sell anything to our customers that we don’t feel is top quality. It’s important to us both to build a business based on reputation and quality, so this has just had to be right (something we kept having to remind ourselves when the whole process felt like it was taking forever…).

So from being total print novices, we now seem to know a lot about printing wall stickers (well, at least Mike does – he is the technical one after all!). And when we started selling our products online we quickly had a number of people enquire about us manufacturing wall stickers for them. As often seems to be the way with a new business, these unplanned opportunities suddenly appear and make a whole lot of sense…I guess we do operate in a pretty specific niche, and if it’s taken us a couple of years of research to get to this point, why not help others who want to sell their designs as wall stickers and become a manufacturer for them? Hopefully the market is big enough for all of us, and we’d like to think we’re a friendly bunch to deal with 🙂

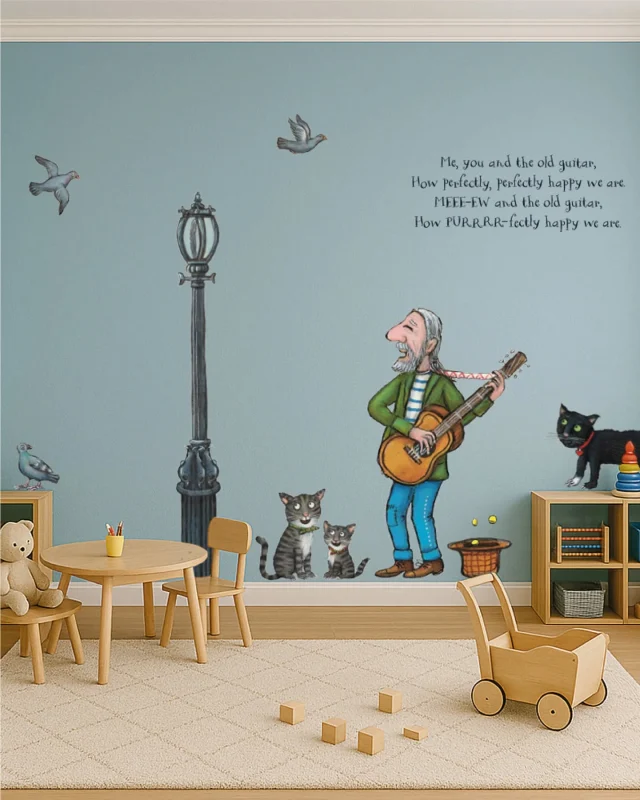

It’s also really exciting to see other people’s products, that we’ve manufactured, come to the market. For instance Mike’s been working with the lovely Chiara at Hoobynooworld (who supplies to Liberty’s no less, I was very impressed!) who has just loaded the first of her new wall sticker products onto her shop. You can check them out here (http://shop.hoobynooworld.co.uk/childrens-wall-stickers/), and also have a browse of her other lovely products that she sells. Here are the stickers mid-production (meet Solly the Sun and Rihanna the Rainbow) and the finished articles on the walls!

As a small business ourselves, we’re big advocates for other small companies, and so we’re happy to manufacture designs with no minimum order commitments, and price reductions for orders of low multiple units. It’s easiest if the design work is already in full digital format, but we can even work with original artwork if necessary and advise on what would work as a sticker and what wouldn’t. So if you’re an artist or designer, or know someone who is, and if you fancy having your designs made into stickers to sell, please do get in touch – we’d love to chat x